1. Take you understand multi gas detector

A multi gas sensor detects a specific gas and measures whether the gas is present near the sensor, or its content in the air. Therefore, gas sensors are often indispensable in safety systems. The gas sensor has many different types and can measure different gases. There are sensors that measure non-toxic gases such as oxygen and carbon dioxide, and sensors that detect toxic gases such as carbon monoxide, TVOC, and ammonia. Multi Gas sensors are often used in flammable, explosive and toxic places to protect workers.

Choosing the right multi-gas detector is essential for ensuring workplace safety. With a wide range of options available in the market, it can be challenging to make the right decision. In this article, we will explore important factors to consider when selecting a multi-gas detector.

Using Multi Gas Detectors for Environmental Monitoring

2.Important factors to consider when selecting a multi gas detector

Identify the Required Gases:

First and foremost, identify the specific gases that need to be detected in your workplace. Different industries may have different gas hazards. Ensure that the detector can accurately detect the gases relevant to your working environment. Common gases include methane, carbon monoxide, hydrogen sulfide, oxygen, and volatile organic compounds (VOCs).

Sensor Performance:

The performance of the sensors in a multi-gas detector is crucial. Look for detectors with high-quality sensors that offer excellent sensitivity and accuracy. The sensors should have a fast response time to provide real-time gas concentration readings. Additionally, choose detectors that have long sensor life and minimal maintenance requirements.

Sensor Configuration:

Consider the configuration of multi gas detector in the detector. Some detectors have fixed sensors, while others allow for sensor customization or interchangeable sensors. Depending on your specific needs, choose a detector that offers the necessary flexibility in sensor configuration.

Detection Range and Alarm Levels:

Check the detection range of the multi-gas detector for each gas. It should cover the minimum and maximum concentrations relevant to your workplace. Additionally, ensure that the detector allows for adjustable alarm levels. This ensures that you can set the thresholds according to the safety standards and regulations applicable to your industry.

Display and User Interface:

The display and user interface of the detector should be intuitive and user-friendly. Choose detectors with clear and easy-to-read displays that provide real-time gas concentration readings. The user interface should be simple to navigate, allowing users to access features and adjust settings easily.

Data Logging and Downloading:

Consider whether data logging capabilities are essential for your workplace. Some multi-gas detectors can store gas concentration data over time, which can be useful for trend analysis and compliance reporting. If data logging is required, ensure that the detector allows for easy downloading of data to a computer or other devices.

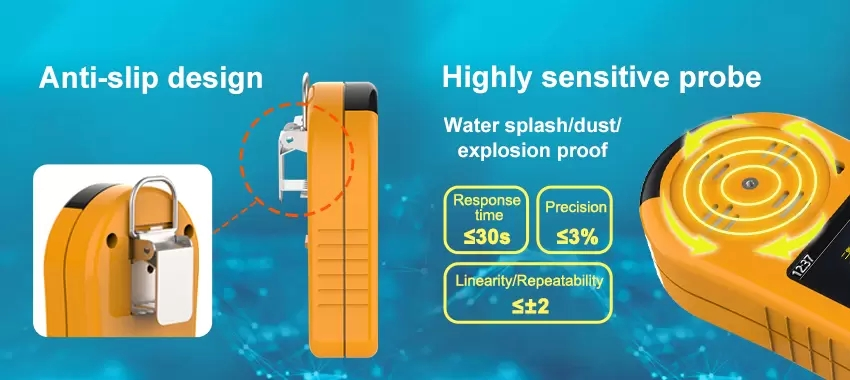

Durability and Robustness:

In many industries, multi-gas detectors are exposed to harsh environments. Therefore, it is crucial to select a detector that is durable and robust enough to withstand such conditions. Look for detectors that are designed to resist water, dust, and impact. Additionally, consider the battery life of the detector to ensure it can last throughout a work shift.

Training and Support:

Lastly, consider the availability of training and technical support for the chosen multi-gas detector. Ensure that the manufacturer or supplier provides comprehensive training on how to use and maintain the detector properly. Additionally, check if they offer reliable technical support in case of any issues or questions.

3.Understand the function and characteristics of multi-gas detector

A multi-gas detector is a versatile device used to detect and monitor the presence of multiple hazardous gases in various environments. These detectors are commonly used in industries such as oil and gas, mining, chemical, firefighting, and environmental monitoring.

Here are some functions and characteristics of multi-gas detectors:

- Gas Detection: Multi-gas detectors can simultaneously detect and measure the concentration of multiple gases, such as combustible gases (e.g., methane, propane), oxygen (O2), carbon monoxide (CO), hydrogen sulfide (H2S), and various toxic gases. This capability allows users to effectively assess potentially dangerous situations and take appropriate actions.

- Real-Time Monitoring: These detectors provide real-time monitoring of gas levels, ensuring immediate awareness of any sudden changes or leaks. They typically have clear displays or alarm systems that indicate the gas concentration, enabling users to respond swiftly and implement necessary safety procedures.

- Compact and Portable: Multi-gas detectors are designed to be compact, lightweight, and portable, enabling easy and convenient transportation. This makes them suitable for a wide range of applications, including confined spaces, remote work locations, and field operations.

- Robust and Durable: Built to withstand harsh environments, multi-gas detectors are often rugged and durable. They are built with protective casings and are resistant to moisture, dust, and accidental drops, ensuring their reliability and longevity even in challenging conditions.

- Alarm Systems: Multi-gas detectors are equipped with audible and visual alarms to alert users when gas levels exceed pre-set thresholds. These alarms provide an immediate warning, allowing workers to evacuate, initiate emergency protocols, or take necessary actions to mitigate risks.

- Data Logging and Connectivity: Many multi-gas detectors include data logging capabilities to record gas concentrations over time. This data can be crucial for incident analysis, regulatory compliance, and safety audits. Some models also offer wireless connectivity options, allowing for real-time data transmission, remote monitoring, and integration with safety management systems.

- Calibration and Maintenance: Multi-gas detectors require periodic calibration to ensure accurate readings. They often come with calibration options, either through manual adjustments or docking stations. Regular maintenance, including sensor replacement and battery checks, ensures their continued performance and reliability.

Conclusion:

Selecting the right multi gas detector requires careful consideration of several factors. By identifying the required gases, assessing sensor performance, considering detection range and alarm levels, evaluating the display and user interface, checking data logging capabilities, ensuring durability, and considering training and support options, you can make an informed decision. Remember, prioritizing workplace safety is paramount, and choosing the right multi-gas detector plays a crucial role in achieving it.